Examine This Report on Premier Aluminum Llc

Examine This Report on Premier Aluminum Llc

Blog Article

The Best Strategy To Use For Premier Aluminum Llc

Table of ContentsNot known Facts About Premier Aluminum LlcPremier Aluminum Llc Can Be Fun For EveryoneThe Ultimate Guide To Premier Aluminum LlcNot known Incorrect Statements About Premier Aluminum Llc

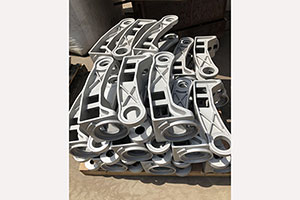

(https://www.edocr.com/v/0onvglma/garymartin53403/premier-aluminum-llc)Generally, a buyer's key responsibility was to discover certified and receptive suppliers. Sometimes, purchasers presumed that any kind of supplier going to contractually fulfill the acquisition need was certified. Nonetheless, making use of affordable and unqualified distributors can cause quality concerns, and squandered time and money over time. To help you via the process, here are some things to think about when choosing the ideal metal casting distributor.

For instance, a business that only uses the financial investment spreading process will try to sell you on why that procedure is best for your application. But what happens if using the sand casting procedure is best for you and your demands? Rather, seek a provider that provides a series of casting procedures so the most effective alternative for YOU is chosen

If functioning with a single resource for every one of your casting requires is very important to you, the vendor requires to be diverse in its abilities. When integrated with other incorporated capabilities, this can help simplify and compress the supply base. When selecting the ideal casting provider, cautious consideration ought to be provided to high quality, service, and price.

More About Premier Aluminum Llc

Purchasers progressively choose casting distributors who have machining capabilities. If the spreading vendor finds a problem during machining, the problem is resolved faster with no disagreement over whose mistake it is.

Problem or no, integrated machining simplifies the supply chain and lowers handling time and shipping expense before the item makes it to the customer. What do you need from your casting supplier? Are you trying to find somebody to just provide a metal element to your front door or do you need more? For example, if you do not have in-house metallurgy know-how, validate that the vendor can offer guidance in picking the proper alloy based on your specific application - Aluminum Casting company.

Some factories are limited or specialized. Make sure the supplier can satisfy all your product or alloy needs to eliminate the demand for several vendors.

The 9-Minute Rule for Premier Aluminum Llc

Research study the distributor's site. Talk to a sales rep or organization associate.

Light weight aluminum is additionally lightweight and has great corrosion resistance, making it excellent for applications where weight and toughness are essential variables. In addition, light weight aluminum casting is a cost-efficient approach of manufacturing, as it needs much less energy and sources than various other methods. Iron casting, on the other hand, involves putting liquified iron into a mold and mildew to create a wanted shape.

The smart Trick of Premier Aluminum Llc That Nobody is Talking About

Iron casting is additionally able to withstand high temperatures, making it suitable for usage in applications such as engine parts and commercial machinery. Iron casting can be extra costly than light weight aluminum casting due to the higher expense of raw materials and the energy required to melt the iron. When determining between light weight aluminum casting and iron spreading, it is important to take into consideration the certain demands of the application.

In conclusion, both light weight aluminum spreading and iron spreading have their own unique benefits and disadvantages. There are three sub-processes that drop under the group of die spreading: gravity die casting (or irreversible mold and mildew spreading), low-pressure die spreading and high-pressure die casting. To get to the finished product, there are 3 key alloys made use of as die casting material to choose from: zinc, aluminum and magnesium. Report this page